Side shifters & load backrest overview

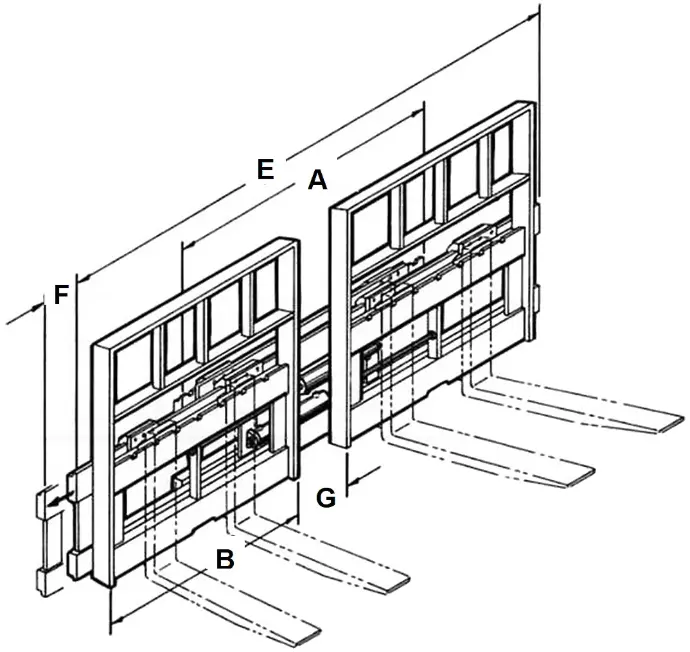

What we need to know (for all types of side shifters):

- Forklift make, model, and capacity.

- The type and width of the base carriage (the truck’s carriage tells us where the SS upper hooks must be spaced).

- Desired width of the side shifter. (Wide SS on a narrow carriage means reinforcement of the fork bars is required. Additional cost.)

- Side shift total distance. 8 inches is standard. Additional SS stroke may not be possible due to the base carriage’s width limitation.

- Is an LBR required? If so, what height (measured from the top of the fork blade)?

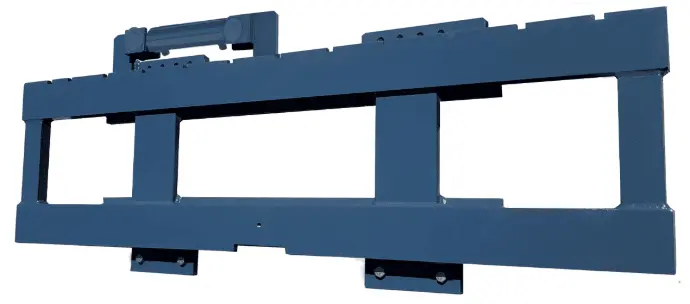

A side shifter is a hydraulically operated attachment used to move the forks laterally across the carriage. It is used for fork and load alignment, increasing handling efficiency. Nearly all forklifts today are factory built with a side shift carriage. These are mixed between standard hang-on (separate attachment from the carriage) and “integral”, a built-in component of the forklift carriage. We make a hang-on style.

One hydraulic function is required to operate a side shifter.

For trucks of 2000 LB up through 17,500 LB capacity @ 24” load center:

Our units are made to order in the desired width for the job.

We use an aluminum bronze upper bearing that is also the top hook of the side shifter mounting. The lower bearing is a plastic block used elsewhere and that we sell as a replacement part for Cascade attachments. Our side shifter accepts standard ITA forks. We can add a load backrest on order.

The term “hook to hook” refers to the side shifter’s mounting type and the fork bars, or the forks’ mounting type. The term reflects that ITA classes are used in both areas. Hook to hook also means the truck’s forks can be used.

Our cylinder is a top mount with a requirement to weld the stationary anchor bracket to the forklift.

This term means that the mounting of the side shifter is hook-type, and the fork mounting bar is pin-type. The common application of these is in lumber yards and building materials yards, where loading flatbeds and yard stacking may cause heel drag of the fork. If no pallet is under the stack, the down force of the mast and carriage, and the drag of the secured hook-type fork, might damage products. The pin-type fork will kick out and lessen the effect of the drag on the lower loads.

As implied, the mounting and the fork bar are pin-type. Tubes connect the side shifter to the pin-type carriage of the forklift. Pin-type forks, often the same forks as were on the truck, are used on the fork bar of the side shift. The mounting tubes of the side shifter are bushed to prevent gouging the forklift carriage pin. The forks are moved manually and do not require bushings.

Fork-Co Leads the Pack

With our industry-best lead times (4-5 weeks on complex builds), full in-house engineering and design team, on-site manufacturing and fabrication facility just south of Houston, TX, and vast standard product inventory, Fork-Co is the right choice for your project. We stand behind our products 100%, either it accomplishes your goals, or we aren't done.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.