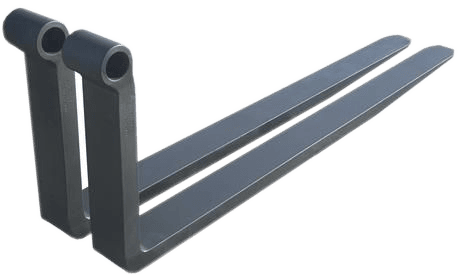

pin-type forks

Why Fork-Co?

Pin Type Forks Done Right

Proprietary Weld Process

Fork-Co employs a proprietary thermally managed weld process to ensure a strong and seamless fork assembly.

Precision Machining

Our on-site precision machine shop ensures no less than perfect pin tube placement and maximum weld prep surface area without sacrificing fork shank or pin tube integrity.

Un-Matched Experience

The Fork-Co fabrication team simply can't be outdone. With decades of experience on the shop floor, we know what works.

Industry-Leading Delivery

We know you can't wait 8-10 weeks for a set of Forks. Our standard lead times for custom forks are 1-2 weeks. Need it faster? We can do that!

We Listen

Not every application fits the traditional knowledge base. We pride ourselves on understanding your application and delivering exactly what you want.

Integrity

It's our guiding principle. When you place your trust in Fork-Co, you are guaranteed that you will be happy with the performance of your product. If you're not, we aren't done.

All our forks are forged, shot-blasted, machined back, sides, and tapers, and are guaranteed to be level at the tips within ISO standards. All Fork-Co smaller (15,000lb or less) Forks are high yield heat-treated alloy steel, ASTM 4140 or 4340. Our larger Forks are 15B37 high yield steel. All our forks undergo individual magnetic powder crack checking.

We keep Fork Blanks in stock for Pin Type applications up to 110,000lb capacity at 48" LC. Larger units are available with a minor lead time.

Request a Quote for Pin Type Forks

Fork-Co Leads the Pack

With our industry-best lead times (4-5 weeks on complex builds), full in-house engineering and design team, on-site manufacturing and fabrication facility just south of Houston, TX, and vast standard product inventory, Fork-Co is the right choice for your project. We stand behind our products 100%, either it accomplishes your goals, or we aren't done.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.