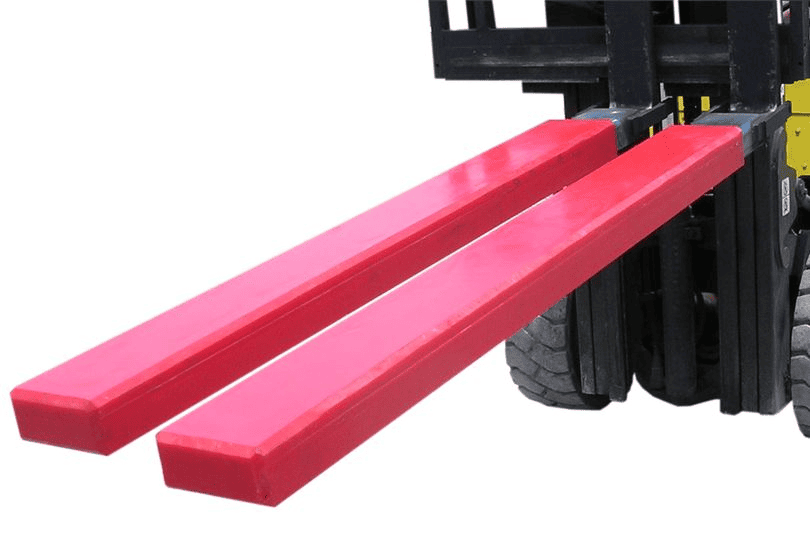

Poly Coated Fork Extensions

- Handling Stainless Steel

- Handling Galvanized, Painted, Epoxy Coated, Plastics, and Finished Wood

- When the fork's corners, tips, or steel blades are a problem

- Extremely durable, lasting much longer than vinyl or fabric style covers

- Installation is by forklift entry. Drive the forks into the rear openings.

- Self-locking pins engage behind the fork heels to secure sleeves to the fork.

- The steel inner sleeve is built to order to fit the host’s forks closely.

- Poly-Coated on 4 or all 5 Faces

-

As a custom-fabricated product with a complex curing process, delivery typically runs 5-7 weeks.

Request a Quote for Poly Encapsulated Extensions / Sleeves

Poly Coated Fork Extensions / Sleeves

These sleeves are used where extreme durability and load protection from carbon steel contact is needed. The poly-coated sleeves are made the same length as the forks since they are not intended to be load-bearing attachments, other than to be under the load resting on the fork. They are retained to the fork using locking pins behind the heels. The poly can be poured to any depth required. Typically, this will be between 3/8” to ½” thick. The 4 and 5-sided models usually get ¾” thick poly all around.

Fork-Co Leads the Pack

With our industry-best lead times (4-5 weeks on complex builds), full in-house engineering and design team, on-site manufacturing and fabrication facility just south of Houston, TX, and vast standard product inventory, Fork-Co is the right choice for your project. We stand behind our products 100%, either it accomplishes your goals, or we aren't done.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.