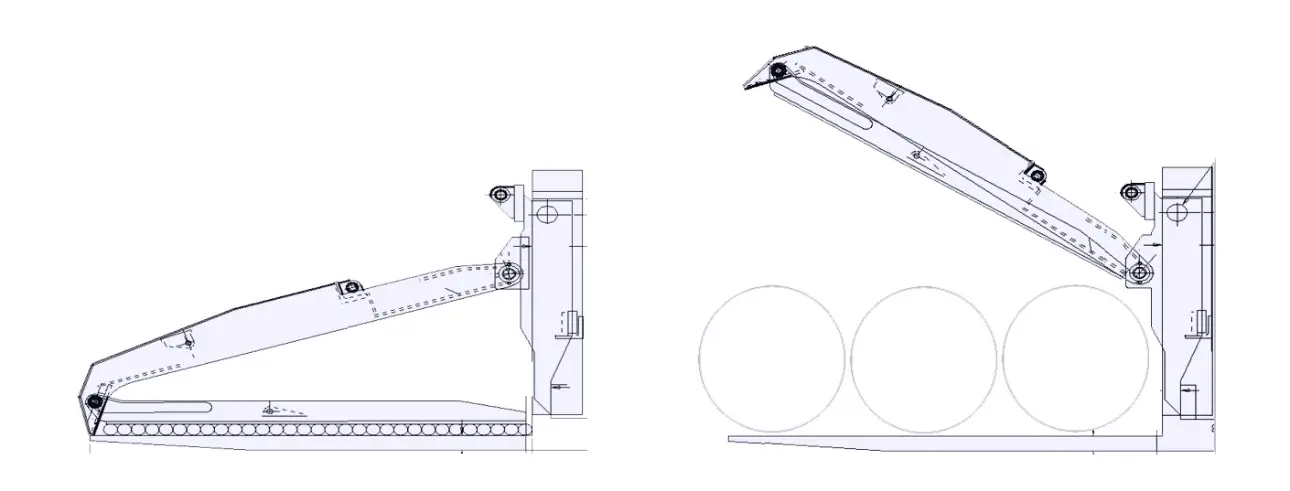

SW Pipe Hold Down Clamp

| Model | Truck Capacity @ LC |

Carriage Width

Min-Max

|

Fork

Length

|

Weight

LBS

|

HCG

Lowered

|

| WPH-SW-MD2 | 18 - 25,000 | 84 - 98 | 96 | 2700 | 41 |

| WPH-SW | 26 - 36,000 @ 24" | 84 - 120 | 96 | 3400 | 46 |

| WPH-SW-HD | 35 - 52,000 @ 48" | 90 - 120 | 96 | 4600 | 46 |

- ALL PIPE CLAMPS IN THE WPH SERIES ARE DESIGNED FOR PIPE DIAMETERS FROM 3 INCHES TO 36 INCHES STANDARD. CONSULT FORK-CO FOR VARIATIONS AS REQUIRED.

- FORK-CO’S UNIT PIPE CLAMPS REQUIRE NO WELDING, CUTTING, OR MODIFICATIONS TO THE ORIGINAL FORKLIFT TRUCK CARRIAGE. OUR CLAMPS EMBED INTO THE FORK CARRIAGE ON THE ORIGINAL FORK MOUNTING BAR.

- SPECIFICATIONS DEPEND ON THE FORKLIFT CARRIAGE AND MOUNTING CONNECTION. DETAILED NUMBERS AND DIMENSIONS ARE DETERMINED AT THE TIME OF QUOTING AND VARY ACCORDING TO THE REQUIRED MOUNTING DIMENSIONS. CONSULT FORK-CO FOR ADDITIONAL INFORMATION. ALL CLAMPS REQUIRE SINGLE-FUNCTION HYDRAULIC SUPPLY. TWO-FUNCTION CONTROLS ARE AVAILABLE ON ORDER. ASK FORK-CO FOR THIS ARRANGEMENT. CLAMP ARM CONTACT SURFACE IS STEEL IN STANDARD CONFIGURATION. PROTECTIVE PADDING IS AVAILABLE. PADS CAN ALSO BE FACTORY-DRILLED FOR FUTURE PADDING INSTALLATION.

- ALL FORK-CO PIPE CLAMPS COME COMPLETE WITH ALL HOSING AND OPERATING VALVES INSTALLED. INSTALLER SUPPLIES THE SHORT CONNECTOR HOSES FROM FORKLIFT TO CLAMP HOSE TERMINATION BULKHEAD LOCATED AT REAR OF THE RIGHT-HAND ARM. MAXIMUM OPERATING PRESSURE RANGE IS 1800 TO 2000 PSI. TRUCK AUXILIARY SETTINGS MUST BE IN COMPLIANCE TO ENSURE SECURE LOAD RETENTION TO PREVENT EXCESS FORK DEFLECTION.

- ALL FORK-CO PIPE CLAMPS ARE MADE IN TEXAS, USA.

- CONSULT FORKLIFT MANUFACTURER FOR ACTUAL RESIDUAL CAPACITY OF THE FORKLIFT WITH THE CLAMP INSTALLED

Request a Quote

Fork-Co Leads the Pack

With our industry-best lead times (4-5 weeks on complex builds), full in-house engineering and design team, on-site manufacturing and fabrication facility just south of Houston, TX, and vast standard product inventory, Fork-Co is the right choice for your project. We stand behind our products 100%, either it accomplishes your goals, or we aren't done.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.