Multi Purpose Rotating & Rigid Arm Carton Clamps

Multi purpose rotating & rigid arm carton clamps are used for handling palletless corrugated fiberboard cartons and boxes, wooden bins and crates, totes and lugs and in many bale applications where totes, bins, Gaylords etc. are common.

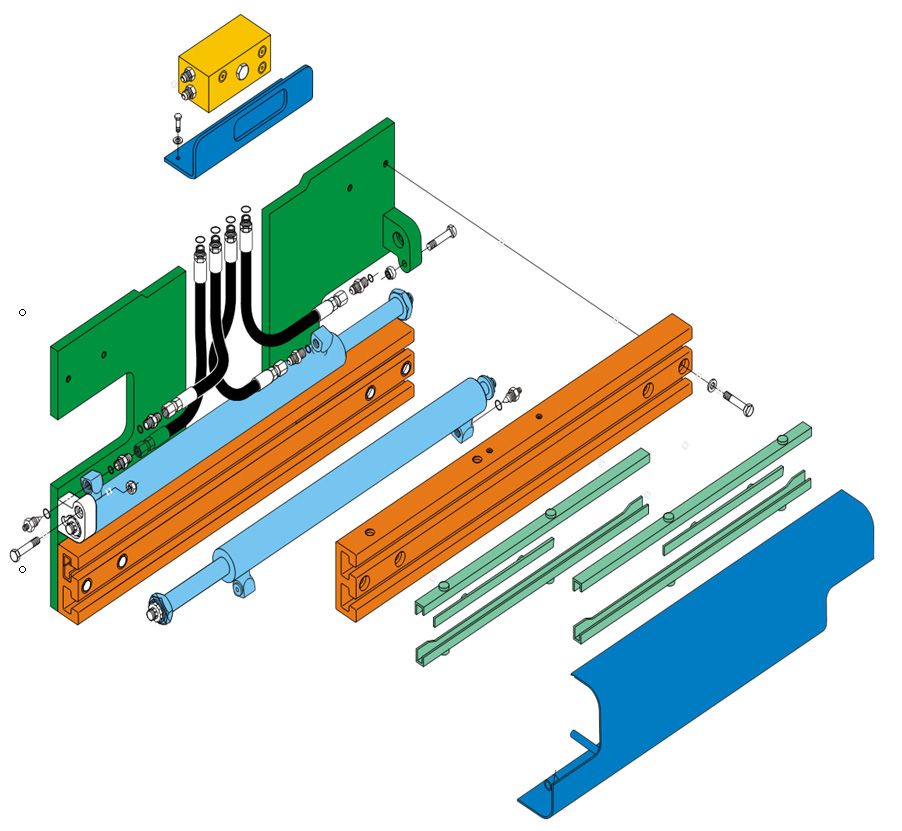

Arms surface is aluminum bonded to vulcanized grooved rubber to ensure secure grip and long life. The bolted rubber surface is replaceable.

Available in standard and custom opening ranges as well as custom arm lengths and heights.

Arms are very thin profile for easy load entry. Tips of the arms are protected by steel guards to preserve the surface integrity.

Features:

Revolving 360 Degree Rotation

Capacities From 3,000 Lb To 7,000 Lb

Adjustable Arm Travel Speeds

E-Profile Aluminum Frame

T-Bar Alloy Steel Arm Carriers

Self-Aligning Cylinders

Lube-Free Contoured Arm Bearings

Cylinder Protection Bumper

Steel Abrasion Protection

Proven Design

Low Profile Frame

Special opening ranges

Arm sizes

Quick change mounting

Bolt-on arms

Solenoid selector valve

Relief valves

Segmented pads

Specifications:

Sideshifting: 2 hydraulic functions required

Non-sideshifting: 1 hydraulic function required

Rotating: 2 hydraulic functions required

Maximum operating pressure: 2000 PSI.

Recommended flow rate:

GBC19D 6-10 GPM

GBC27D 10-14 GPM

Bonded, grooved rubber contact pads provided needed friction to reduce squeeze force required for handling. Bonding to aluminum plates makes the rubber extremely durable

.

360 DEGREE ROTATING MULTI PURPOSE & RIGID ARM CARTON CLAMP

NOTE: Capacity of the truck with an attachment may be less than the attachment capacity shown here. Always consult the forklift manufacturer for actual capacity.

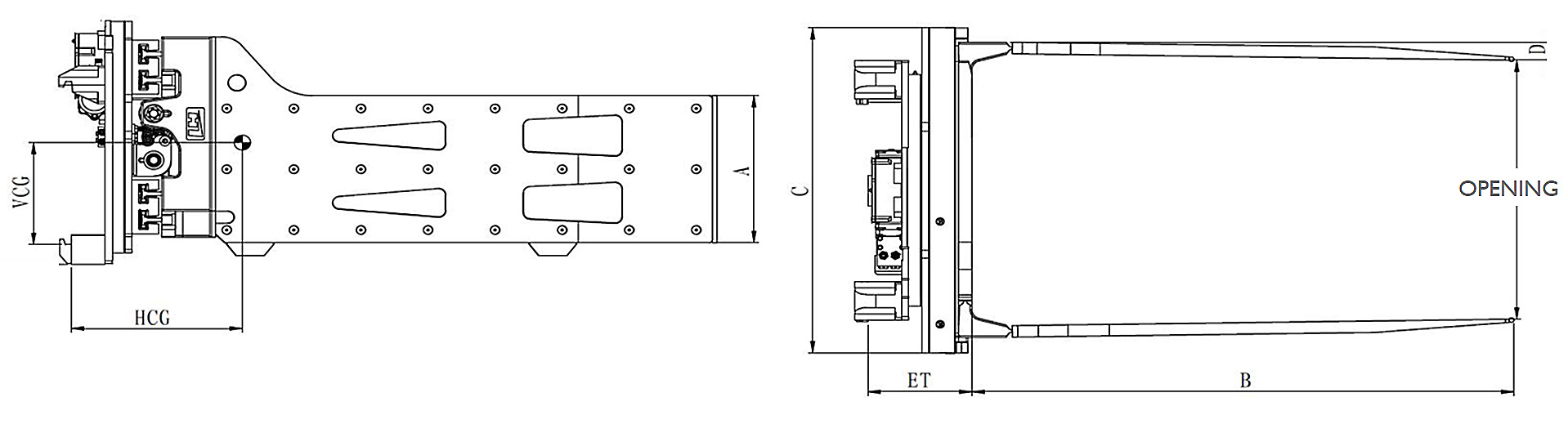

|

Catalog

|

Mounting

Class |

Opening |

HT A |

LGTH B |

FRAME |

Arm |

VCG |

WT / LB |

WT / LB |

HCG |

|

| 3500 |

GA20D-MCR-02A |

Ⅱ |

22-70 |

18 | 40 | 41 | 2.5 | 13.4 | 1505 | 10.5 | 13.75 |

|

3500 |

GA20D-MCR-01A |

Ⅱ |

22-70 |

24 | 36 | 41 | 3 | 13.4 | 1475 | 10.5 | 11.5 |

Fork-Co Leads the Pack

With our industry best lead times (4-5 weeks on complex builds), full in-house engineering and design team, on-site manufacturing and fabrication facility just south of Houston, TX, and very large standard product inventory, Fork-Co is the right choice for your project. We stand behind our products 100%, either it accomplishes your goals, or we aren't done.